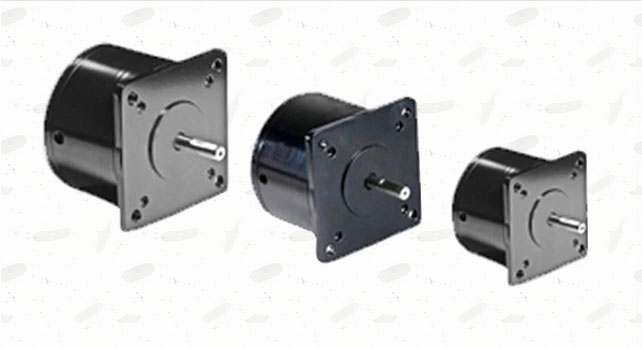

AC Synchronous Motors

GENERAL SPECIFICATION

- Advantage of Synchronous Motor in Motion Control System

- Cost Effective Solution in designing of Motion Control System

- No burn out Low RPM.

| Parameter | Tolerance |

| Step | 1.8°±0.5% Non-Cumulative |

| Resistance | ±10% |

| Inductance | ±30% |

| Temperature Rise | 65°C Max at Motor Flange |

| Ambient Temperature Range | -10°C + 50°C |

| Storage Temperature Range | -10 °C+ 50°C |

| Insulation Resistance | 100 M Min. 500VDC |

| Die Electric Strength | 1500 VAC 1 min |

| Radial Play | 0.50 mm |

| Axial Play | 0.50 mm Max |

APPLICATIONS OF SYNCHRONOUS MOTOR :

- Servo Stabilizer

- Capacitor testing machine

- Slide projector

- Enamelled wire tasting machine

- Paper testing machine

- Diamond Cutting Machines

- Conveyor Belt System

- Food processing industries

- Photo printing machine

- 3 phase variable transformer

- PCB drilling machine

- Advertisement Display Machinery

- Automobile industries

- Over Load tap phase for oil transformer

FEATURES :

- Instantaneous starting, stopping and reversing characteristics.

- Low shaft speeds 60 RPM at 50 Hz.

- D.C. can lock rotor magnetically.

- No burnouts due to locked Rotor.

- Can be over driven without any damage.

- 60 rpm at 50 Hz.

- Special design - 72 rpm at 60 Hz and 110 v or 230 VAC.

- No burnouts at 230 volts even if overload or shaft jammed.

- Instantoneous start, stop, reverse.

- Hold ac motor.

- Preferred coupling; flexible, rubberized.

- Single phase and 3 phases with Scott Transformer.

- Phase Shifting Resistor and Capacitors must be used while operating these motors from single-phase supply. However recommended to use two phases.

- Transformer for higher torque motors.

- Tested on Scott Transformer at factory.

CATALOGUE OF SYNCHRONOUS MOTOR :

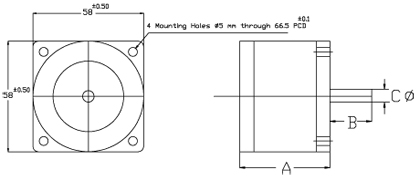

| Type | Torque Kg cm | Voltage Volts | Current Ampere/Phase | Resistance | Inductance mH | ø mm | Length mm | Weight InKg. (Approx.) |

Watts |

| SYN 601 | 2 | 240 | 0.085 | 1.1 KΩ | 4.3 | 56.50 | 59 | 0.6 | 24 |

| SYN 980 | 3 | 240 | 0.110 | 840 Ω | 3.3 | 86.20 | 65 | 1.3 | 39 |

| SYN 981 | 7 | 240 | 0.120 | 840 Ω | 3.2 | 86.20 | 65 | 1.5 | 39 |

| SYN 982 | 14 | 240 | 0.135 | 770 Ω | 4.2 | 86.20 | 78 | 2.0 | 46 |

| SYN 983 | 20 | 240 | 0.170 | 770 Ω | 3.2 | 86.20 | 78 | 2.0 | 55 |

| SYN 1100 | 10 | 240 | 0.18 | 850 Ω | 6.8 | 108 | 77 | 3.2 | 60 |

| SYN 1101 | 20 | 240 | 0.25 | 172 Ω | 1.6 | 108 | 92 | 3.5 | 84 |

| SYN1101(S) | 28 | 240 | 0.32 | 200 Ω | 1.7 | 108 | 110 | 4.5 | 108 |

| SYN 1102 | 40 | 240 | 0.425 | 97 Ω | 1 | 108 | 140 | 5.4 | 144 |

| SYN 1103 | 60 | 240 | 0.665 | 92 Ω | 1.3 | 108 | 165 | 7.3 | 192 |

Extra Accessories / Special Models :

- Connector

- Back Shaft

- Extra Shaft Length

- Extra Cable Length

- Spur Gear Box Heat Sink

TERMS :

- The above prices are Net Ex-our Works, Pune basis, exclusive of Forwarding, Insurance and Freight.

- Forwarding Transit Insurance and Freight at the actual applicable for Outstation supplies only.

- Excise Duty, Sales Tax as and if applicable at the rate prevailing at the time of Delivery of the materials.

- The above price list supersedes all previous price list and be subject to change with notice.

- Standard length of wires will not be less than 500 mm.

- Heat Sink and RC network will be available on request at Extra Cost.

- Installation and commissioning charges will be Extra.

- For Bulk quantity ie. more than 25 nos. Special Discount will be offered.

- Company reserves the right to change Design Data and Dimension without intimation.

- Company reserves the right to change the price without intimation.

NOTE: Assuming Stepper / Synchronous Motor speed 60 RPM reduction speed is given Gear Box and Heat Sink are suitable for SYN 1100, 1101, 1101(S), 1102, 1103, 980, 981, 982, 983, 985.